Produkte

SECALL-CAN

High-reliability fleet management system for open-pit mines for increased production and reduced downtimes.

Fleet management systems have become an essential tool in modern mining operations. The baseline functionality of real-time position awareness of dump trucks, wheel loaders, excavators, and more already allows for route optimizations and maximizes productivity capacity per hour.

Incorporating the trucks’ status information from the CAN-bus, TPMS data, and additional sensors are the next step in telemetry. The TKPH values can be maintained in a safe range while providing appropriate transport capacity. Constantly monitoring motor, gearbox, and suspension data allows for better repair and maintenance decisions.

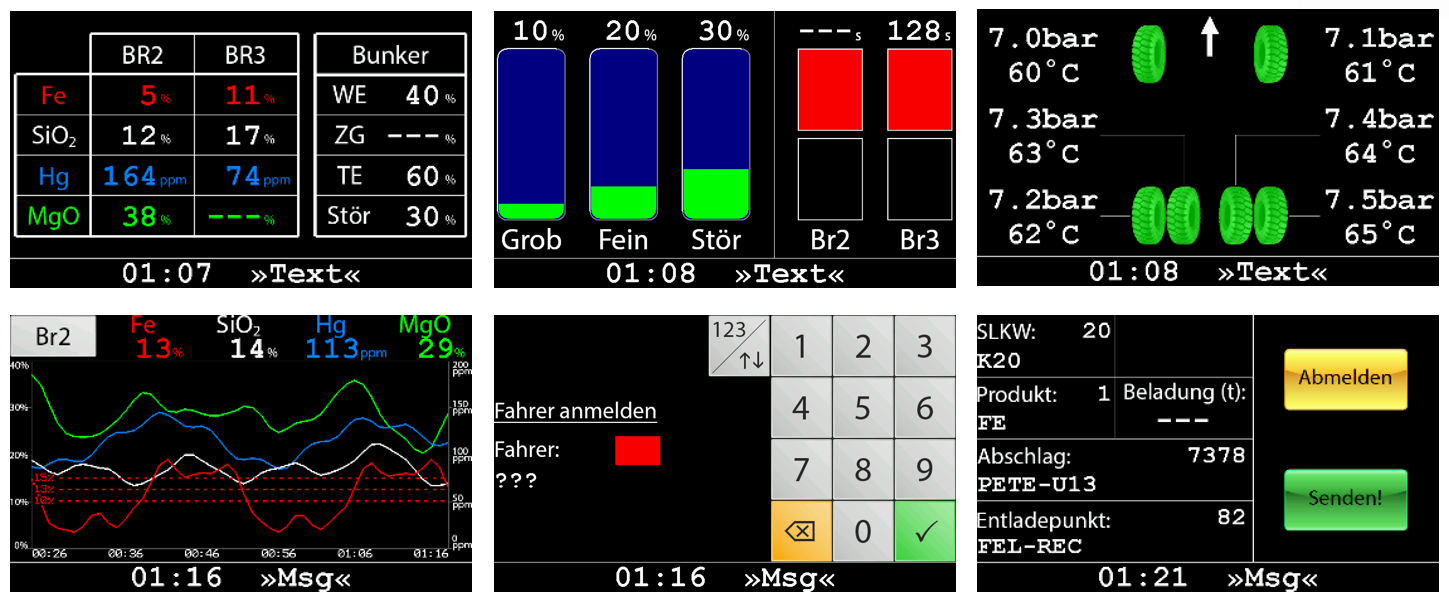

Further steps in real-time fleet analytics are manifold, e.g., analysis of road conditions, traffic routing, automatic dispatching. HMI touch screens can complete such systems for interacting with the driver, reducing/eliminating voice radio communication.

The fleet management system Secall-CAN is a scalable solution concerning both fleet size and functionality. Consequently, the system can grow with the mining operation and its increasing demands on new features. With a long history in fleet management systems, Secall-CAN is Datamatix’answer for open-pit mining operations. Its high degree of customization, scaling capabilities, and reliability are field-proven in central Europe's largest open-pit mine for many years.

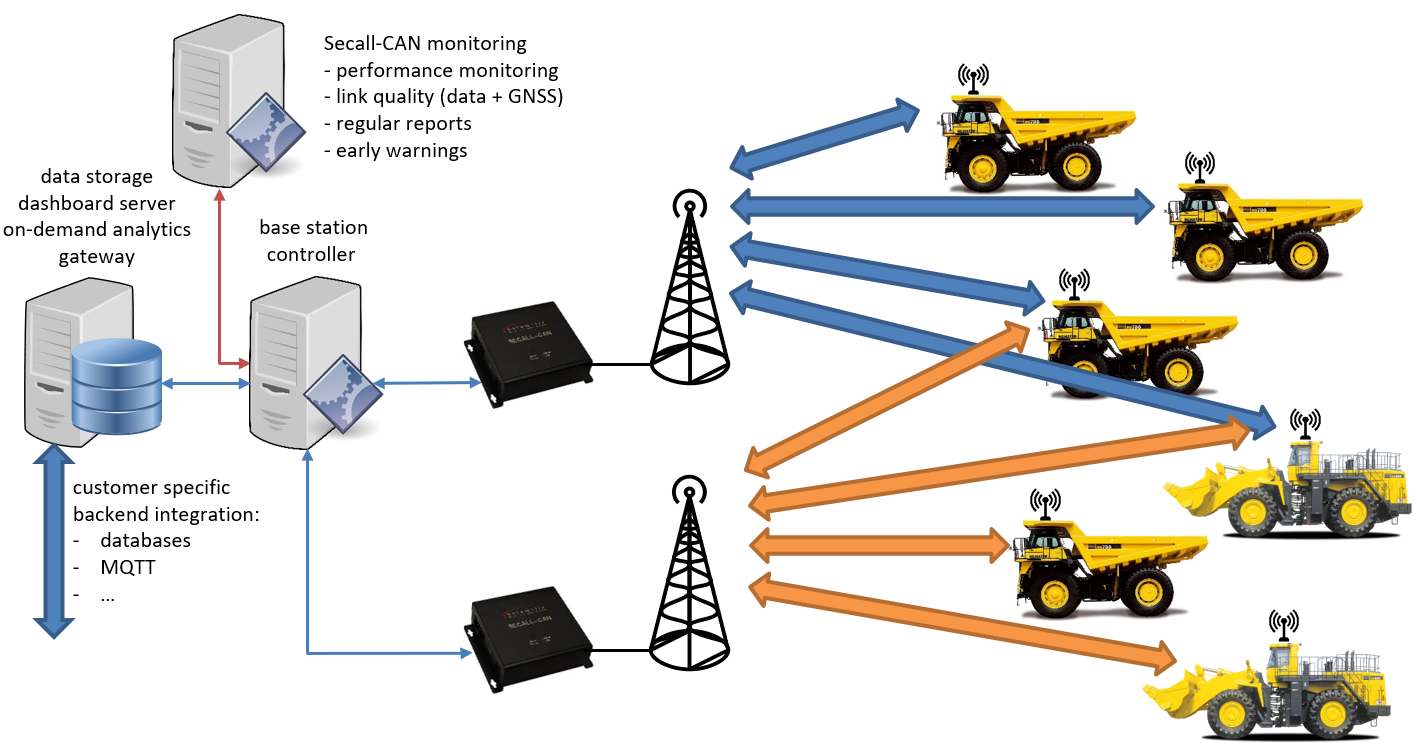

Secall-CAN is a combined hardware/software solution designed for high reliability. Using a dedicated data radio, operated on a licensed frequency, and running all software components on-premises, Secall-CAN does not rely on external networks or cloud services. In a typical configuration with multiple base stations and virtualized server infrastructure, single point of failures are eliminated, guaranteeing high reliability.

Simplified block diagram of a typical Secall-CAN installation.

The Secall-CAN hardware comes with a truck-specific harness, making its installation remarkably simple. Third-party equipment, e.g., TPMS systems, scales, are integrated according to customer requirements and is combined with CAN-bus data for telemetry. With many years of experience in reverse-engineering CAN-bus data, Datamatix offers integration of almost any mining equipment.

Secall-CAN does not come with a standard configuration. By evaluating the customer's needs, the system is tailored for each vehicle operating in the pit. If a feature is missing, it will be rolled out via OTA-update while the truck is in full operation – no need to stop in the workshop. And, for the unlikely case of a hardware defect, a single spare unit can be configured within a minute to replace any other Secall-CAN unit, even if it is a base station.

HMI screens customized to the customer’s application.

For more information, contact office@datamatix.at.

LoRaWAN UniNode

Long-range wireless networks meet high-reliability industrial applications

Wireless communication is considered a key enabling technology of the last decades and has become ubiquitous nowadays. While applications in the private sector continually strive for higher bitrates, industrial use-cases require stable data links. In typical applications, the wireless connection to remote sensors and actuators takes use of existing mobile networks. Unfortunately, the operators of those networks optimize for profit but not for reliability. If a wireless system requires exceptional reliability, companies must operate their own radio infrastructure, typically using proprietary radio protocols.

LoRaWAN, the long-range wireless area network, manages to bridge the gap between public and private network infrastructure. The fully standardized radio protocol allows both to use end-devices with the steadily increasing number of public networks and private (company-owned) infrastructure. With communication ranges of several kilometers, a few base stations can cover a large geographic area. Hence, overlapping radio cells are with ease, preventing a single point of failure (SPOF).

As the LoRaWAN end-device itself, therefore, has become the weakest link in the chain, DATAMATIX specializes in the development of professional LoRaWAN nodes, tailed to the customer’s needs, and rated for the most demanding industrial applications. For example, features include high-security cryptographic key storage, redundant power supplies, and multi-radio solutions. DATAMATIX end-nodes of course support LoRaWAN classes B and C, making them ideal for actuator applications as well.

UniNode series end-device, designed for a specific customer application. The node includes 50 A current sensors, analog/digital IOs, supervised high power drivers, current loop interfaces, RS232/422/485 connectivity, and extensions for HMI touchscreens. The main application is a fully supervised, remote actuator with AES128 encrypted communications.

DATAMATIX is a full solution provider for LoRaWAN systems and offers the design of professional LoRaWAN nodes, planning/installation of networks, and the development and integration of applications on both server and node side. Additional services include stress testing and reliability analysis of LoRaWAN modules, systems, and networks.

For more information, contact office@datamatix.at.

Alte Produkte: Wir sind gewohnt, dass unsere Produkte viele Jahre, und länger als geplant, bei unseren Kundinnen und Kunden im Einsatz sind. Wenn Sie noch eines dieser alten Produkte in Verwendung haben und Unterstützung benötigen, kontaktieren Sie uns bitte: ADM, DEMADIS, CADICOS, SECALL, SECALL – AST, MOBICARD, Datenfunklösungen mit KENWOOD und ICOM